Annealsys DLI-CVD technology

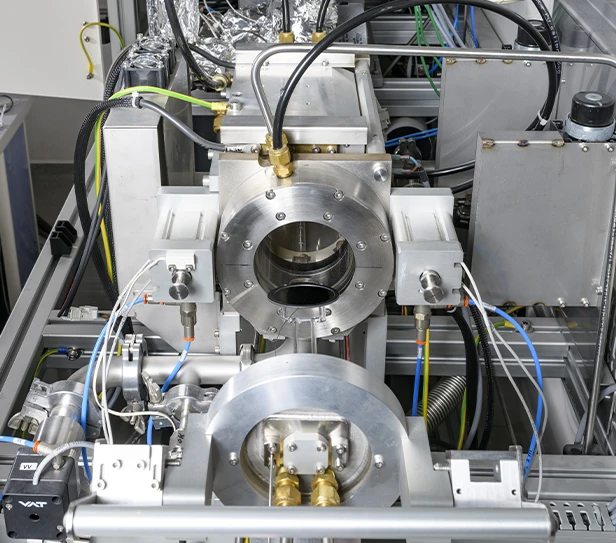

These machines offer multi process capabilities inside the same process chamber: CVD, ALD, MOCVD, pulse pressure CVD and RTP, RTCVD for the MC-050.

DLI CVD and ALD

Processes.

Applications: optical waveguides, optical coating, MIMS capacitors, microwave integrated circuit, superconductors, ferroelectric memories, bioactive and biocompatible coatings, thermal and anticorrosion barriers, micro-batteries and more.

Processes and

Substrates.

Processes:

- Simple and multi-metallic oxides (see application notes)

- Nitrides, metals, and alloys

- 2D and 3D materials

- III-V, wide band gap semiconductors

Substrates:

- Silicon – Compound semiconductor – Single crystals – Silicon carbide wafers

- Poly silicon wafers for solar cells

- Glass substrates

- Metals

- Others

Deposited

Materials.

- Oxides: BaO, Y2O3, Cr2O3, TiO2, Al2O3, HfO2, Li2O, SiO2, LIPON, Bi2O3, Co3O4, CuCrO2, SiO2, LiNbO3, LaNiO3, SiZrOx, SrTiO3, BaTiO3, MovCrwFexBiyOz

- 2D materials: Graphene, h-BN, TMDs (MoS2, WS2, etc.)

- Metals: Pt, Mo, W, Ru ….

- Nitrides: TiN, AlN

Advantages of our technology

Our DLI

Technology.

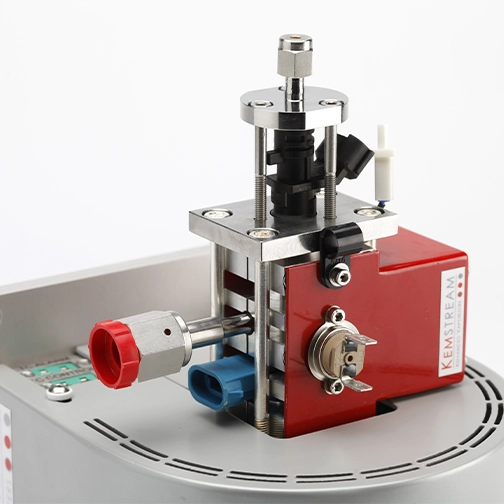

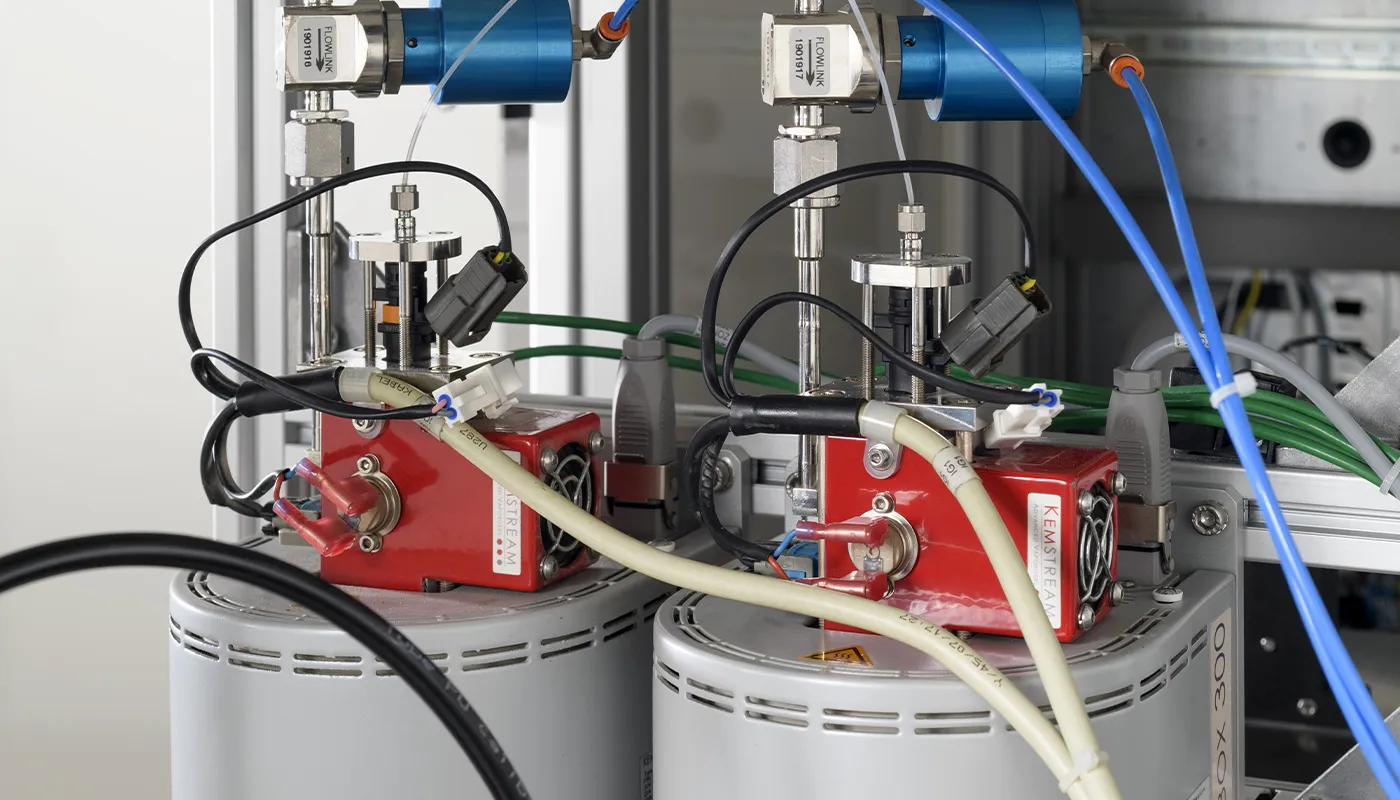

DLI vaporizers can handle both liquid and solid chemical precursors. Solid precursors need to be dissolved into an organic solvent. The technology is a particularly well suited method for low vapor pressure and thermally unstable liquid or solid ALD and CVD precursors.

Exceptional Multi-Process Capability

Annealsys DLI-CVD machines support a wide variety of deposition processes CVD, ALD, MOCVD, pulse-pressure CVD, plus in-situ RTP and RTCVD, all within the same process chamber.

Thermalized Chamber Walls

Annealsys DLI-CVD reactors are designed with thermally controlled walls that focus deposition solely onto substrates, avoiding unwanted deposition on chamber walls which simplifies cleaning and maintenance.

Fine Precursor Flow Control

The DLI vaporizers enable accurate liquid flow control, fast on/off vapor switching, minimal dead volume and efficient precursor usage. This helps in achieving sharp interface control, accurate control of doping levels and reduced chemical consumption.

Precursor container remains at room temperature

In the DLI-CVD systems the chemical precursors are stored into special and pressurizzed stainless steel tanks. The precursors remain at room tempeature until they are injected into the vaporizers for the process. This avoid decomposition of the chemicals into the precursor tanks.

Design and Maintenance

These systems are engineered for low maintenance, with low operational costs, and high reliability, which makes them attractive for long-term use in both R&D and production.

Our systems

Applications

Guidelines.

These machines can perform different types of processes inside the same chamber: DLI-CVD, DLI-ALD, DLI pulse pressure CVD. The two-inch machine can in addition run infrared assisted ALD and CVD, RTP, RTCVD and MOCVD processes.

DLI-CVD / DLI-ALD processes

Processes

Acronyms.

DLI

Direct Liquid Injection

CVD

Chemical Vapor Deposition

ALD

Atomic Layer Deposition

MOCVD

Metal Organic Chemical Vapor Deposition

Do you have a question or a project?

For any further information, do not hesitate to contact us to find out more about our products and services.