Leading Rapid Thermal Processing expertise

The cold wall chamber technology and the extended temperature range of our Rapid Thermal Processing associated with optimized susceptors allow processing the widest range of substrates : Silicon wafers / Compound semiconductor wafers / GaN and Sapphire wafers for LEDs / Silicon carbide wafers / Poly silicon wafers for solar cells / Glass substrates / Metals / Polymers

RTP and RTCVD

Processes.

Our RTP / RTCVD systems are used for many different types of R&D applications to production. The main productions applications are: power devices, sensors, MEMS, optoelectronics, telecommunication devices, discrete components, laser diodes, etc.

RTP

Processes.

Resident reactions processes in which heat is applied to modify already existing materials structure in or on the wafer with no additional external materials.

- Implant and Ohmic contac annealing

- Diffusion of dopants

- Densification and crystallization

- Thermal annealing of polymers

Surface interaction processes in which heat causes modification of the wafer surface by gases spread over it : Oxidation, nitridation, selenization, silicon carbonization.

RTCVD

Processes.

In CVD, the gases react with the surface of the heated substrate to form a thin layer. The chemical reaction is activated by heat, photons and plasma. Annealsys is specialized in thermal and photon assisted processes.

- RTCVD of graphene (see application note)

- RTCVD of hBN (hexagonal boron nitride)

Advantages of our technology

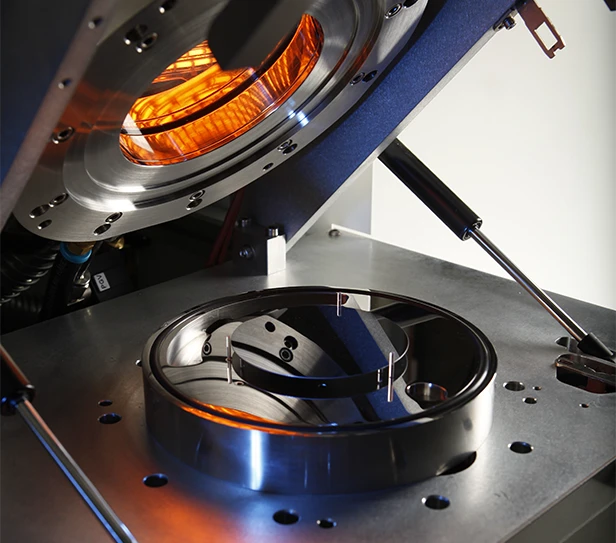

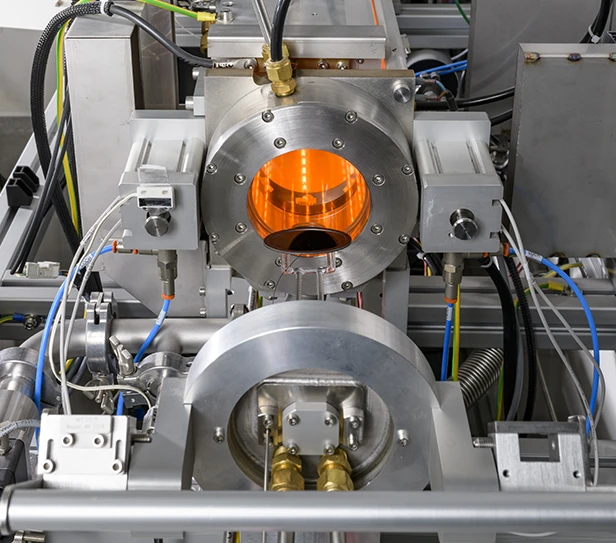

Cold Wall Chamber

RTP.

The cold wall chamber technology and Annealsys reactor design offer a range of advanced features that enhance process efficiency and reliability. These features ensure precise, consistent, and high-performance results in various applications.

High Process Reproducibility and Low Memory Effect

Cold wall chamber technology and Annealsys reactor design ensure high process reproducibility. The process chamber remains at a consistent temperature, resulting in a low memory effect.

Cooling Rates and Clean Environment

These systems achieve higher cooling rates and maintain an ultra-clean, contamination-free environment. This eliminates metallic and cross contamination, ensuring the integrity of the process.

Accurate Temperature Measurement

Accurate pyrometer temperature measurement is achieved without interference from lamp signals. Additionally, low temperature pyrometer control can go down to 150°C or less, providing precise temperature management.

Advanced Temperature Control

The fast digital RTP temperature controller, combined with a multi-zone cross lamp furnace (AS-One Plus, AS-Premium & AS-Master), enhances precision and control over the process.

Gas Mixing and Distribution

The reactors feature gas mixing capability and uniform gas distribution over the sample. They also offer both atmospheric and standard vacuum capabilities, with an optional turbo pump for enhanced performance.

Design and Maintenance

The design includes a minimum volume and reduced surface area for high vacuum performance. It also allows for easy chamber cleaning and offers an optional fast cooling feature, making maintenance straightforward and efficient.

Advanced

Automation.

These features provide a high versatility of our systems and offer the widest range of Rapid Thermal Processing applications including resident reaction, surface interaction and deposition processes. It also allows the capability to anneal thermally sensitive substrates.

The cold wall chamber, the extended temperature range as well as the high vacuum capabilities offer the possibility to process high temperature resistant substrates (GaN, SiC, ceramics) as well as temperature sensitive substrates like polymers.

Applications

Guidelines.

These machines can perform different types of rapid thermal annealing and rapid thermal chemical vapor deposition processes.

Implant annealing - Ohmic contact annealing - Diffusion of dopants - Densification and crystallization - Oxidation - Nitridation - Selenization

Thermal annealing of polymers - CVD of graphene - CVD of h-BN (hexagonal boron nitride) - Silicon carbonization

RTP / RTCVD Processes

Processes

Acronyms.

RTP

Rapid Thermal Processing

RTA

Rapid Thermal Annealing

RTO

Rapid Thermal Oxidation

RTN

Rapid Thermal Nitridation

CVD

Chemical Vapor Deposition

RTCVD

Rapid Thermal Chemical Vapor Deposition

LPCVD

Low Pressure Chemical Vapor Deposition

Do you have a question or a project?

For any further information, do not hesitate to contact us to find out more about our products and services.