Products

DLI/CVD Systems

DLI-CVD is the most efficient technology for the deposition of new materials. It provides unique vaporization capabilities and the possibilty to deposit most of the elements of the periodic table.

Applications: optical waveguides, optical coating, MIMS capacitors, microwave integrated circuit, superconductors, ferroelectric memories, bioactive and biocompatible coatings, thermal and anticorrosion barriers, micro-batteries and more.

Unique vaporization capabilities

Multiprocess systems

Annealsys is developing processes for the deposition of multi metallic oxides, metal, transition metal nitrides layers and also 2D materials including graphene, hexagonal boron nitride and transition metal dichalcogenides (TMDs). Machines are available for substrates up to 50 mm, 100 mm or 200 mm diameter.

Small 3D parts (few centimeters size) can be processed in the 50 mm machine. Our DLI deposition systems offer multiprocess capabilities inside the same process chamber: DLI-CVD, DLI-ALD, MOCVD, pulse pressure CVD and even in-situ rapid thermal processing (RTP) for the MC-050.

DLI-CVD Range

DLI/CVD & DLI/ALD

Innovative Systems.

MC-050

2-inch

DLI-CVD System.

The Annealsys MC-050 system is a 2-inch DLI-CVD reactor for research and development. The infrared lamp furnace and the system design provide multi process capability inside the same process chamber: CVD, ALD, RTP and RTCVD.

MC-100

100 mm

DLI-CVD system.

The Annealsys MC-100 system is designed for DLI-CVD and DLI-ALD processes. The MC-100 has a vertical low temperature wall reactor and can receive different types of liquid delivery and vaporization apparatus.

MC-200

200 mm

DLI-CVD system.

The Annealsys MC-200 system is designed for DLI-CVD and DLI-ALD processes. The MC-200 has a vertical low temperature wall reactor and can receive different types of liquid delivery and vaporization apparatus.

DLI/CVD systems

Why choose

Our DLI/CVD Systems.

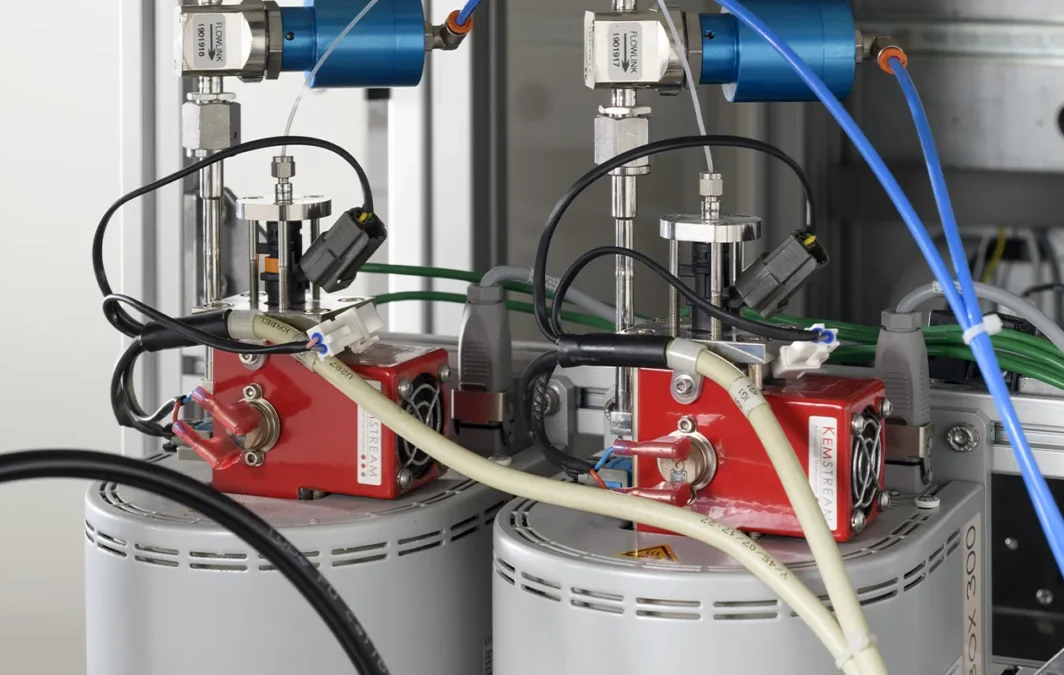

The direct liquid injection technology provides the highest flexibility for utilization of a wide range of chemical precursors for the development of new materials. Our machines come with state of the art liquid distribution equipment for enhanced chemical precursor handling.

Exceptional Multi-Process Capability

Annealsys DLI tools support a wide variety of deposition processes—DLI-CVD, DLI-ALD, MOCVD, pulse-pressure CVD, plus in-situ RTP and RTCVD, all within the same process chamber.

Broad Precursor Compatibility

These systems can handle low vapor pressure precursors, thermally unstable chemicals and diluted or air-sensitive materials. This versatility expands the palette of usable chemistries.

Fine Precursor Flow Control

The DLI vaporizers enable accurate liquid flow control, fast on/off vapor switching, minimal dead volume and efficient precursor usage. This helps in achieving sharp interface control and reduced chemical consumption.

Lower COO & Easy Maintenance

These systems are engineered for low maintenance, with low operational costs, and high reliability, which makes them attractive for long-term use in both R&D and production.

Do you have a question or a project?

For any further information, do not hesitate to contact us to find out more about our products and services.