Products

Rapid Thermal Processing Equipment

Since 2004, Annealsys designs and manufactures Rapid Thermal Processing Equipment from R&D to production applications. Since 2022, Jipelec RTP systems manufactured for more than 40 years are part of Annealsys portfolio. Our process experts support our customers with a strong backgroud and expertise for the right selection of the product to match their needs.

Annealsys, partner for your complex applications

Extended temperature range and vacuum capability

The infrared lamp furnaces can perform annealing up to 1450°C under atmosphere or vacuum. Applications include Rapid Thermal Annealing (RTA) processes like ohmic contact annealing, implantation annealing, etc. as well as Rapid Thermal Chemical Vapor Deposition (RTCVD) of graphene or hexagonal Boron Nitride (h-BN).

These versatile Rapid Thermal Procesing equipment can process samples from few mm up to 200 mm diameter with manual loading or cassette to cassette robot handling for production, including customized solutions for processing compound semiconductor wafers with susceptors. The high temperature Zenith system can run process at 2000°C for 1 hour.

RTP Range

Our line of

Rapid Thermal Processing equipment.

Find the tool that meets your requirements.

Jipelec JetLight

2-inch

RTA System.

The JetLight is a 2-inch rapid thermal annealing system with vacuum capability.

AS-Micro

3-inch

RTP System.

AS-Micro is an economical 3-inch RTP system adapted for laboratories and universities.

AS-One

4 and 6-inch

RTP systems.

Versatile Rapid Thermal Processing cold wall chamber furnaces: 4-inch and 6-inch version

AS-Premium

6-inch RTP

With double side heating.

Multiconfiguration RTP platform for silicon and compound semiconductor wafers up 150 mm diameter

AS-Master

200 mm

RTP System.

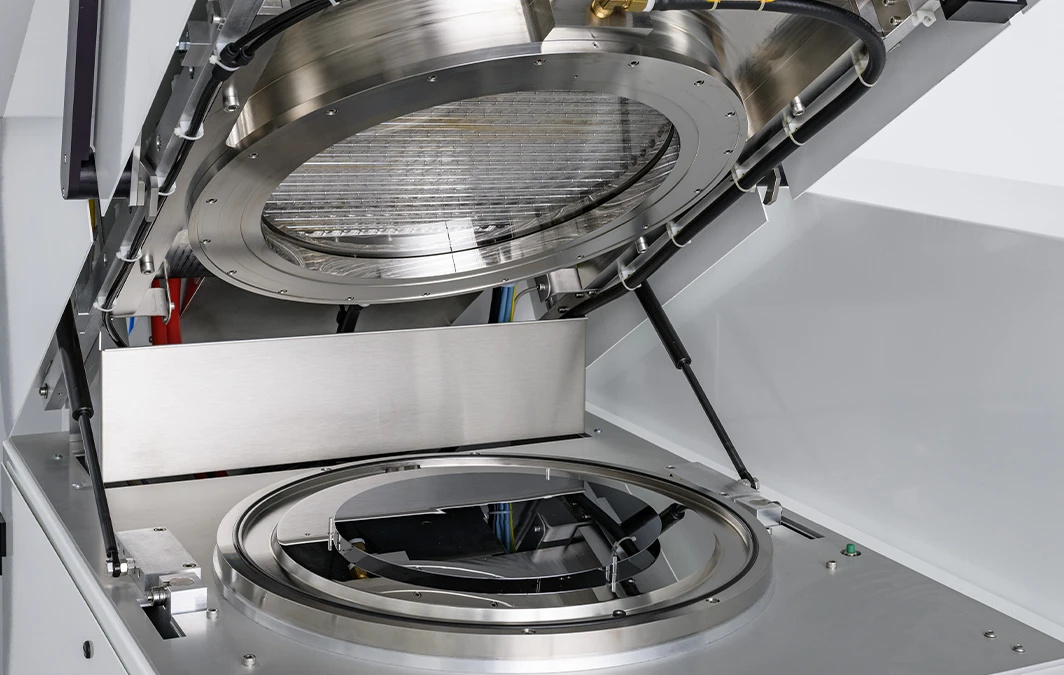

Versatile 200 mm cold wall chamber RTP system for R&D and production. From RT up to 1450°C down to 10-6 Torr.

Jipelec JetFirst

200 mm and 300 mm

RTP Tools.

200 mm and 300 mm cold wall chamber RTA systems.

ZENITH Series

RTP at 2000°C.

The Zenith systems are vailable in two sizes to process wafers up to 100 mm or 200 mm diameter at temperature up to 2000°C. They have been specially developed to meet the requirements of universities research laboratories. The system has a stainless steel water-cooled chamber. The cold wall chamber technology provides significant advantages: high process reproducibility, low memory effect, higher cooling rates.

Why choose our

Rapid Thermal Processing equipment ?.

Annealsys RTP (Rapid Thermal Processing) systems are chosen by research laboratories and semiconductor manufacturers for several technical and strategic reasons.

Process Flexibility

Support for a wide range of processes: annealing, oxidation, nitridation, diffusion, silicidation, densification, crystallization, and more. Compatible with both research-scale development and pilot/production environments.

Innovation

Proprietary state of the art temperature controller insuring accurate and overshootless temperature profiles. Pulse annealing capability to keep the bulk substrate at lower temperature.

Uniformity & Repeatability

Advanced lamp-based heating design ensures wafer temperature uniformity, even across larger substrates (from small dies to 200 mm wafers). Excellent repeatability for reproducible R&D and manufacturing.

Proven Reliability & Support

Established reputation in universities, research centers, and high-tech industries worldwide. Backed by responsive technical support and process expertise.

Do you have a question or a project?

For any further information, do not hesitate to contact us to find out more about our products and services.